BacTech Environmental Corporation

Financing Requirement:

BacTech Environmental Corporation (“BacTech” or the “Company”) is currently seeking CAD$24M through a debt instrument.

FOR more information, please contact

Marshall Farris at 604-837-4774 or marshall@ascentafinance.com.

About the Company:

BacTech Environmental Corporation (“BacTech” or the “Company”) is a proven environmental technology company, delivering effective and eco-friendly bioleaching and remediation solutions to commercial operations to process and recover preferred metals (gold, silver, cobalt and copper) and safely remove and transform harmful contaminants like arsenic into benign EPA-approved products for landfill. Tapping into numerous environmental and economic advantages of its proprietary method of bioleaching, BacTech uses naturally occurring bacteria, harmless to both humans and the environment, to neutralize toxic mining sites with high-pay potential. The Company’s Zero Waste initiative (see below) aligns with its commitment to innovation, environmental responsibility, and the circular economy.

BacTech’s bioleaching process liberates precious and base metals from difficult to treat and generally harmful ores, concentrates, and tailings. BacTech's environmentally friendly processing benefits extend beyond the remediation of tailings and other mining stockpiles. Their solution strikes balance and considers benefits towards the planet, people, and profit.

BacTech plans to build a new owner-operated bioleaching facility near Ponce Enriquez, Ecuador, in a region where arsenic is associated with gold ore (Arsenopyrite). The Company plans to build a 50 tpd bioleaching plant to treat high gold/arsenic material. A 50 tpd plant, processing 1.95 ounces of gold per tonne of feed, similar to feeds available to the Company from local miners, would produce approximately 30,900 ounces per year. Plant designs are modular and can be expanded without affecting ongoing production. The total concentrate market in the Ponce Enriquez area is estimated to be between 200 and 250 tonnes per day, allowing for increased potential with a larger plant.

Click here to view the BacTech Website

Click here to view the BacTech Presentation

Click here to view a ZeroTailingsTM Information Sheet

Investment Highlights

The Bankable Feasibility Study (BFS) on BacTech’s Tenguel, Ecuador bioleach facility, conducted by an independent third-party engineering group, and filed by BacTech on SedarPlus, used US$1,600 per ounce for gold and US$18 per ounce for silver in its financial modeling. The study projected a profit of US$11 million at US$1,600 gold. The project has a US$20 million capital cost to build the facility. With the price of gold reaching a new high, breaking through US$3,000 per ounce (as of June 2025), the rate of return on capital becomes even more attractive.

Zero Waste Initiative

On April 7, 2025 BacTech filed a full patent for its Zero Waste Initiative, setting a new standard in sustainable mining and resource recovery. This breakthrough innovation was validated through rigorous testing at Mirarco in Sudbury, Canada, under the direction of BacTech’s Dr. Paul Miller.

BacTech’s patented process enhances the economic potential of mine waste by integrating bioleaching with a unique combination of downstream processing steps. This approach converts iron sulphides, such as pyrrhotite, into a suite of high-value, saleable products. The process not only aligns with global sustainability goals, it allows for the possibility of cleaning up legacy mine sites (such as an estimated 80 million tonnes in the Sudbury Basin, etc., source Douglas Duffy et al 2015, U. of Toronto) but also unlocks untapped revenue streams across multiple industries.

Disruptive Innovation: Turning Waste into Marketable Commodities

The Zero Waste process represents a paradigm shift in mineral waste management by extracting and monetizing valuable elements:

High-Purity Magnetite Iron: A critical input for the Green Steel sector, this furnace-,ready iron feedstock eliminates the carbon emissions associated with traditional iron ore mining and processing. It also holds high value for the pigment industry.

Ammonium Sulphate Fertilizer: A strategically vital agricultural input, BacTech’s process ensures independent production of this organic fertilizer, reducing reliance on petroleum-derived sulphur and stabilizing supply chains.

Nickel, Copper, Cobalt and Rare Earths Recovery: These strategic base metals are precipitated out as high-purity commodities, supporting critical minerals supply and the global shift toward electrification.

Silicate Residue for Construction: The remaining inert materials can be repurposed as backfill or incorporated into geopolymer-based construction materials, reducing waste disposal challenges.

A Market-Ready, De-Risked Solution for Global Mining Waste

With approximately 12 billion tonnes of fresh tailings generated annually by the global mining industry, BacTech’s Zero Waste patent presents a massive opportunity to transform mine waste into sustainable resources. The process has been de-risked by integrating well-established equipment and processing methods in a novel sequence, combined with BacTech’s proprietary bioleaching expertise.

Unlocking Investment & Industry Adoption

A key advantage of BacTech’s approach is its ability to generate diverse and resilient revenue streams:

Fertilizer Production: The highest revenue contributor, addressing global agricultural demand while reducing price volatility risks.

Magnetite Iron Sales: A scalable, high-value input for both Green Steel and pigment industries.

Base Metal Recovery: Nickel, copper, and cobalt extraction provides strategic value.

This revenue diversification significantly enhances the financial viability of long-term mineral waste treatment projects, making them attractive to investors previously deterred by commodity price volatility.

Environmental Benefits

No roasting or smelting. It is a water-based leaching process with no gas emissions

Green chemistry: uses ammonia rather than acids or exotic chemicals

Organic fertilizer: produces ammonium sulphate via microbial extraction qualifying product as a premium organic fertilizer.

Custom iron feedstocks: tailored iron products reduce environmental impacts for steelmakers.

Converts mine waste into an alternative supply of metals and fertilizers lowering global mining demand and emissions.

Eliminates the need to generate acid for fertilizer production using sulphide minerals to generate organic fertilizer. This delinks fertilizer producers from petroleum-based sulphur supply chains.

How Complex Is the Technology

The process is simple and robust using standard tanks and settling systems under atmospheric pressure and moderate temperatures

Avoids complex machinery and high-risk technologies ensuring reliability and ease of operation

The process is designed for scalability and adaptability making it ideal for remote geography.

The technology is built on proven industrial technologies

Advancing the Green Steel Revolution

Green Steel aims to eliminate carbon emissions in steel production by integrating renewable energy and waste-minimization technologies. BacTech’s Zero Waste process directly supports this initiative by supplying high-grade magnetite iron, eliminating the need for carbon-intensive virgin ore mining. This presents a unique opportunity for steel producers to secure sustainable, low-carbon raw materials.

Strategic Impact on Resource Independence

Beyond its economic and environmental benefits, BacTech’s Zero Waste initiative contributes to resource security for governments and industries worldwide. By converting waste into valuable, domestically sourced commodities, the process reduces reliance on imported iron, fertilizer, and critical base metals, reinforcing supply chain resilience and national strategic resource independence. It also reduces the need for fresh mining and processing, given the quantity of usable metal and byproducts now available because of this invention.

Exchange: CSE

Symbol: BAC

(ALSO: OTCBB: BCCEF, FSA: 0BT1)

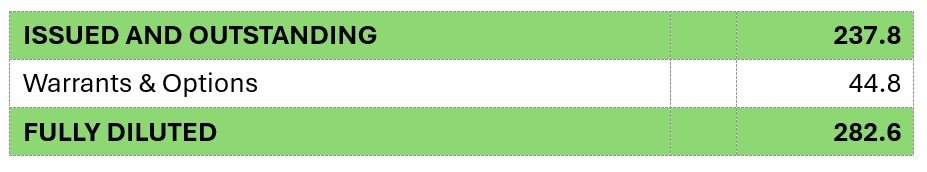

Corporate Structure:

Recent Corporate News:

December 1, 2025

BacTech Announces Appointment of Brett Whalen to the Board of Directors

November 4, 2025

BacTech Strengthens Balance Sheet Through Convertible Debenture Restructuring, Reducing Outstanding Debt

September 30, 2025

BacTech Environmental Corporation Mourns the Passing of Don Whalen

May 23, 2025

BacTech Closes Oversubscribed Unit Financing: Exceeds Initial Goal of $1M by 26.6%

March 31, 2025

BacTech Announces Second Closing of Unit Financing

March 7, 2025

BacTech Closes First Tranche of Unit Financing

February 28, 2025

BacTech Announces Latest Capital Raise

November 25, 2024

BacTech Announces CBOE Approval of Royal Transaction with Silver Crown

October 25, 2024

BacTech Environmental Receives First Tranche of Silver Crown Royalties Shares

July 15, 2024

BacTech Secures Funding to Advance “Zero-Waste” Patent for Pyrrhotite

May 31, 2024

BacTech Signs Letter of Intent to Sell a Portion of its Annual Silver Production to Silver Crown

April 19, 2024

BacTech Environmental Corporation Appoints the President of Ecuador’s Chamber of Mines, Carolina Orozco, to Board of Directors

April 5, 2024

BacTech Environmental Unveils Intellectual Property for‘Zero-Waste’ Metals Recovery & Fertilizer Production

January 16, 2024

BacTech Provides a Follow-Up Update on Sudbury Pyrrhotite Tailings R&D Project

November 18, 2023

BacTech Environmental Receives Final ESIA Permit Approval from Ecuadorian Government to Begin Development of Bioleach Processing Facility in Tengu

BacTech in the News:

October 15, 2025: Proactive Investors - BacTech Environmental Pioneers Cleaner Metal Extraction with Bioleaching, Expands Ecuador Operations

September 16, 2025: Green Success Stories - The Green Spotlight

Our Bugs Eat Rocks – Mobilizing Social and Environmental Sustainability Across the Mining and Resource Sectors

January 6, 2025: Streetwise Reports

Is Ecuador’s Environment Improving At All?

September 9, 2024: Triple Pundit

From the Petri Dish to the Mine - These Microbes Dissolve Minerals

May 9, 2024: Streetwise Reports

Green Tech CEO Says Ecuador Deal Good Sign for Troubled Country

November 27, 2023: Global Mining Review

BacTech Environmental Receives Approval for Bioleach Processing Facility in Ecuador

June 7, 2022: CBC News

Toronto company looks to extract billions in value from Sudbury mine waste

The Technology:

Conventional gravity/flotation to remove sulphides from ore/tailings to make high-grade gold/arsenic concentrate

Sulphides are the source of acid release but also contain the valuable metal to be recovered

Bioleaching of arsenopyrite (arsenic/sulphide ore) concentrates produced from mining and/or tailings

The technology is commercially proven

BacTech has “in-house” capacity for the design, construction and operation of the plant

It is a continuous process which is safe, easy to operate and flexible

Scalable in a short period of time and capable of processing a wide variety of low to high grade concentrates